What are the Product Features of Current Sensing Resistors?

I. Introduction

A. Definition of Current Sensing Resistors

Current sensing resistors, also known as shunt resistors, are precision resistors used to measure the flow of electric current in a circuit. By placing a resistor in series with a load, the voltage drop across the resistor can be measured, allowing for the calculation of current based on Ohm’s Law. These components are essential in various applications, from power management to battery monitoring.

B. Importance of Current Sensing in Electronic Circuits

In modern electronic circuits, accurate current measurement is crucial for performance optimization, safety, and efficiency. Current sensing resistors enable designers to monitor and control current flow, ensuring that devices operate within their specified limits. This capability is particularly important in applications such as battery management systems, where overcurrent can lead to damage or failure.

C. Overview of the Article

This article will explore the fundamental principles of current sensing resistors, their key features, performance metrics, applications, selection criteria, and future trends. By understanding these aspects, engineers and designers can make informed decisions when integrating current sensing resistors into their designs.

II. Basic Principles of Current Sensing Resistors

A. Ohm’s Law and Its Relevance

Ohm’s Law states that the current (I) flowing through a conductor between two points is directly proportional to the voltage (V) across the two points and inversely proportional to the resistance (R) of the conductor. This relationship is fundamental to the operation of current sensing resistors, as the voltage drop across the resistor is used to calculate the current flowing through the circuit.

B. How Current Sensing Resistors Work

When a current flows through a current sensing resistor, a voltage drop occurs across the resistor. This voltage drop can be measured using a microcontroller or an analog-to-digital converter (ADC). The current can then be calculated using the formula:

\[ I = \frac{V}{R} \]

where \( V \) is the measured voltage drop and \( R \) is the resistance value of the sensing resistor.

C. Types of Current Sensing Techniques

There are several techniques for current sensing, including:

Shunt Resistor Method: The most common method, where a low-value resistor is placed in series with the load.

Hall Effect Sensors: These sensors measure the magnetic field generated by the current flow, providing a non-intrusive method of current measurement.

Current Transformers: Used primarily in AC applications, these devices measure current by transforming it into a proportional voltage.

III. Key Features of Current Sensing Resistors

A. Resistance Value

1. Tolerance Levels

The resistance value of a current sensing resistor is critical for accurate current measurement. Tolerance levels indicate how much the actual resistance can vary from the specified value. Common tolerance levels range from ±1% to ±5%, with lower tolerances providing higher accuracy.

2. Temperature Coefficient

The temperature coefficient of resistance (TCR) indicates how much the resistance changes with temperature. A low TCR is desirable for current sensing resistors, as it ensures stable performance across varying temperatures.

B. Power Rating

1. Maximum Power Dissipation

Current sensing resistors have a specified power rating, which indicates the maximum power they can dissipate without overheating. Exceeding this rating can lead to resistor failure and inaccurate measurements.

2. Thermal Management

Effective thermal management is essential for maintaining the performance and reliability of current sensing resistors. Designers must consider heat dissipation methods, such as heat sinks or thermal vias, to ensure that resistors operate within safe temperature limits.

C. Size and Form Factor

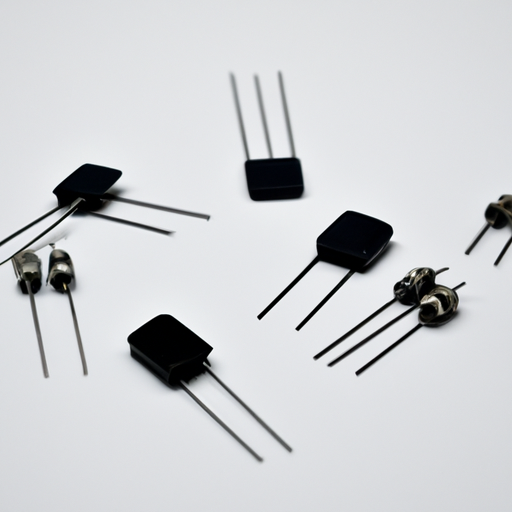

1. Surface Mount vs. Through-Hole

Current sensing resistors come in various sizes and form factors, including surface mount (SMD) and through-hole types. SMD resistors are preferred for compact designs, while through-hole resistors may be used in applications requiring higher power ratings.

2. Impact on PCB Design

The size and placement of current sensing resistors can significantly impact PCB design. Designers must consider factors such as trace width, current path, and thermal management when integrating these components into their layouts.

D. Material Composition

1. Metal Film vs. Wirewound

Current sensing resistors can be made from different materials, including metal film and wirewound. Metal film resistors offer better stability and lower noise, while wirewound resistors can handle higher power levels but may have higher inductance.

2. Influence on Performance and Reliability

The choice of material affects the performance and reliability of current sensing resistors. High-quality materials can enhance accuracy, stability, and lifespan, making them suitable for demanding applications.

E. Noise Characteristics

1. Voltage Noise

Voltage noise can affect the accuracy of current measurements. Current sensing resistors should have low voltage noise characteristics to minimize measurement errors.

2. Thermal Noise

Thermal noise, generated by the resistor itself, can also impact performance. Designers should consider the noise characteristics of resistors when selecting components for sensitive applications.

F. Frequency Response

1. Bandwidth Considerations

The frequency response of current sensing resistors is crucial for applications involving high-frequency signals. A resistor with a wide bandwidth can accurately measure current in fast-switching circuits.

2. Impedance Effects

The impedance of the current sensing resistor can affect the overall circuit performance. Designers must account for the impedance when integrating these resistors into their designs.

IV. Performance Metrics

A. Linearity and Accuracy

Linearity refers to how accurately the output voltage corresponds to the input current across the entire measurement range. High linearity ensures that the current sensing resistor provides consistent and reliable measurements.

B. Response Time

The response time of a current sensing resistor is the time it takes for the resistor to respond to changes in current. Fast response times are essential for applications requiring real-time monitoring and control.

C. Stability Over Temperature and Time

Current sensing resistors should maintain stable performance over varying temperatures and extended periods. Stability is crucial for ensuring accurate measurements in diverse operating conditions.

D. Reliability and Lifespan

The reliability and lifespan of current sensing resistors are critical factors in their selection. High-quality resistors are designed to withstand environmental stresses and provide long-term performance.

V. Applications of Current Sensing Resistors

A. Power Management Systems

Current sensing resistors are widely used in power management systems to monitor and control power consumption, ensuring efficient operation of electronic devices.

B. Battery Management Systems

In battery management systems, current sensing resistors help monitor charging and discharging currents, preventing overcurrent conditions that could damage batteries.

C. Motor Control Applications

Current sensing resistors are essential in motor control applications, providing feedback for current regulation and protection against overload conditions.

D. Renewable Energy Systems

In renewable energy systems, such as solar inverters, current sensing resistors are used to monitor energy flow and optimize system performance.

E. Consumer Electronics

Current sensing resistors are found in various consumer electronics, enabling features such as battery life monitoring and power optimization.

VI. Selection Criteria for Current Sensing Resistors

A. Application Requirements

When selecting current sensing resistors, it is essential to consider the specific requirements of the application, including current range, accuracy, and response time.

B. Environmental Considerations

Environmental factors, such as temperature, humidity, and vibration, can impact the performance of current sensing resistors. Designers should choose resistors that can withstand the conditions of their intended environment.

C. Cost vs. Performance Trade-offs

Designers must balance cost and performance when selecting current sensing resistors. While high-performance resistors may offer better accuracy and reliability, they may also come at a higher cost.

D. Manufacturer Specifications

Reviewing manufacturer specifications and datasheets is crucial for understanding the performance characteristics and limitations of current sensing resistors.

VII. Future Trends in Current Sensing Resistors

A. Advances in Materials and Technology

Ongoing advancements in materials and technology are leading to the development of more efficient and reliable current sensing resistors. Innovations in manufacturing processes and materials can enhance performance and reduce costs.

B. Integration with Smart Systems

As electronic devices become smarter, the integration of current sensing resistors with smart systems is expected to increase. This integration will enable more sophisticated monitoring and control capabilities.

C. Miniaturization and Enhanced Performance

The trend toward miniaturization in electronics is driving the development of smaller, more efficient current sensing resistors. These components will continue to evolve to meet the demands of compact and high-performance applications.

VIII. Conclusion

A. Recap of Key Features

Current sensing resistors play a vital role in modern electronics, providing accurate current measurement and enabling efficient operation. Key features such as resistance value, power rating, size, material composition, and noise characteristics are essential considerations for designers.

B. Importance of Choosing the Right Current Sensing Resistor

Selecting the appropriate current sensing resistor is crucial for ensuring accurate measurements and reliable performance in electronic circuits. Designers must carefully evaluate application requirements, environmental factors, and manufacturer specifications.

C. Final Thoughts on the Role of Current Sensing Resistors in Modern Electronics

As technology continues to advance, the importance of current sensing resistors will only grow. Their ability to provide real-time current monitoring and control is essential for optimizing performance and ensuring the safety of electronic devices.

IX. References

A. Academic Journals

- IEEE Transactions on Industrial Electronics

- Journal of Electronic Materials

B. Industry Reports

- Market Research Reports on Current Sensing Technologies

- Industry Analysis on Power Management Solutions

C. Manufacturer Datasheets

- Datasheets from leading manufacturers of current sensing resistors, such as Vishay, Bourns, and Ohmite.

This comprehensive overview of current sensing resistors highlights their significance in electronic design and the critical features that engineers must consider when selecting these components. By understanding the principles and applications of current sensing resistors, designers can enhance the performance and reliability of their electronic systems.

What are the Product Features of Current Sensing Resistors?

I. Introduction

A. Definition of Current Sensing Resistors

Current sensing resistors, also known as shunt resistors, are precision resistors used to measure the flow of electric current in a circuit. By placing a resistor in series with a load, the voltage drop across the resistor can be measured, allowing for the calculation of current based on Ohm’s Law. These components are essential in various applications, from power management to battery monitoring.

B. Importance of Current Sensing in Electronic Circuits

In modern electronic circuits, accurate current measurement is crucial for performance optimization, safety, and efficiency. Current sensing resistors enable designers to monitor and control current flow, ensuring that devices operate within their specified limits. This capability is particularly important in applications such as battery management systems, where overcurrent can lead to damage or failure.

C. Overview of the Article

This article will explore the fundamental principles of current sensing resistors, their key features, performance metrics, applications, selection criteria, and future trends. By understanding these aspects, engineers and designers can make informed decisions when integrating current sensing resistors into their designs.

II. Basic Principles of Current Sensing Resistors

A. Ohm’s Law and Its Relevance

Ohm’s Law states that the current (I) flowing through a conductor between two points is directly proportional to the voltage (V) across the two points and inversely proportional to the resistance (R) of the conductor. This relationship is fundamental to the operation of current sensing resistors, as the voltage drop across the resistor is used to calculate the current flowing through the circuit.

B. How Current Sensing Resistors Work

When a current flows through a current sensing resistor, a voltage drop occurs across the resistor. This voltage drop can be measured using a microcontroller or an analog-to-digital converter (ADC). The current can then be calculated using the formula:

\[ I = \frac{V}{R} \]

where \( V \) is the measured voltage drop and \( R \) is the resistance value of the sensing resistor.

C. Types of Current Sensing Techniques

There are several techniques for current sensing, including:

Shunt Resistor Method: The most common method, where a low-value resistor is placed in series with the load.

Hall Effect Sensors: These sensors measure the magnetic field generated by the current flow, providing a non-intrusive method of current measurement.

Current Transformers: Used primarily in AC applications, these devices measure current by transforming it into a proportional voltage.

III. Key Features of Current Sensing Resistors

A. Resistance Value

1. Tolerance Levels

The resistance value of a current sensing resistor is critical for accurate current measurement. Tolerance levels indicate how much the actual resistance can vary from the specified value. Common tolerance levels range from ±1% to ±5%, with lower tolerances providing higher accuracy.

2. Temperature Coefficient

The temperature coefficient of resistance (TCR) indicates how much the resistance changes with temperature. A low TCR is desirable for current sensing resistors, as it ensures stable performance across varying temperatures.

B. Power Rating

1. Maximum Power Dissipation

Current sensing resistors have a specified power rating, which indicates the maximum power they can dissipate without overheating. Exceeding this rating can lead to resistor failure and inaccurate measurements.

2. Thermal Management

Effective thermal management is essential for maintaining the performance and reliability of current sensing resistors. Designers must consider heat dissipation methods, such as heat sinks or thermal vias, to ensure that resistors operate within safe temperature limits.

C. Size and Form Factor

1. Surface Mount vs. Through-Hole

Current sensing resistors come in various sizes and form factors, including surface mount (SMD) and through-hole types. SMD resistors are preferred for compact designs, while through-hole resistors may be used in applications requiring higher power ratings.

2. Impact on PCB Design

The size and placement of current sensing resistors can significantly impact PCB design. Designers must consider factors such as trace width, current path, and thermal management when integrating these components into their layouts.

D. Material Composition

1. Metal Film vs. Wirewound

Current sensing resistors can be made from different materials, including metal film and wirewound. Metal film resistors offer better stability and lower noise, while wirewound resistors can handle higher power levels but may have higher inductance.

2. Influence on Performance and Reliability

The choice of material affects the performance and reliability of current sensing resistors. High-quality materials can enhance accuracy, stability, and lifespan, making them suitable for demanding applications.

E. Noise Characteristics

1. Voltage Noise

Voltage noise can affect the accuracy of current measurements. Current sensing resistors should have low voltage noise characteristics to minimize measurement errors.

2. Thermal Noise

Thermal noise, generated by the resistor itself, can also impact performance. Designers should consider the noise characteristics of resistors when selecting components for sensitive applications.

F. Frequency Response

1. Bandwidth Considerations

The frequency response of current sensing resistors is crucial for applications involving high-frequency signals. A resistor with a wide bandwidth can accurately measure current in fast-switching circuits.

2. Impedance Effects

The impedance of the current sensing resistor can affect the overall circuit performance. Designers must account for the impedance when integrating these resistors into their designs.

IV. Performance Metrics

A. Linearity and Accuracy

Linearity refers to how accurately the output voltage corresponds to the input current across the entire measurement range. High linearity ensures that the current sensing resistor provides consistent and reliable measurements.

B. Response Time

The response time of a current sensing resistor is the time it takes for the resistor to respond to changes in current. Fast response times are essential for applications requiring real-time monitoring and control.

C. Stability Over Temperature and Time

Current sensing resistors should maintain stable performance over varying temperatures and extended periods. Stability is crucial for ensuring accurate measurements in diverse operating conditions.

D. Reliability and Lifespan

The reliability and lifespan of current sensing resistors are critical factors in their selection. High-quality resistors are designed to withstand environmental stresses and provide long-term performance.

V. Applications of Current Sensing Resistors

A. Power Management Systems

Current sensing resistors are widely used in power management systems to monitor and control power consumption, ensuring efficient operation of electronic devices.

B. Battery Management Systems

In battery management systems, current sensing resistors help monitor charging and discharging currents, preventing overcurrent conditions that could damage batteries.

C. Motor Control Applications

Current sensing resistors are essential in motor control applications, providing feedback for current regulation and protection against overload conditions.

D. Renewable Energy Systems

In renewable energy systems, such as solar inverters, current sensing resistors are used to monitor energy flow and optimize system performance.

E. Consumer Electronics

Current sensing resistors are found in various consumer electronics, enabling features such as battery life monitoring and power optimization.

VI. Selection Criteria for Current Sensing Resistors

A. Application Requirements

When selecting current sensing resistors, it is essential to consider the specific requirements of the application, including current range, accuracy, and response time.

B. Environmental Considerations

Environmental factors, such as temperature, humidity, and vibration, can impact the performance of current sensing resistors. Designers should choose resistors that can withstand the conditions of their intended environment.

C. Cost vs. Performance Trade-offs

Designers must balance cost and performance when selecting current sensing resistors. While high-performance resistors may offer better accuracy and reliability, they may also come at a higher cost.

D. Manufacturer Specifications

Reviewing manufacturer specifications and datasheets is crucial for understanding the performance characteristics and limitations of current sensing resistors.

VII. Future Trends in Current Sensing Resistors

A. Advances in Materials and Technology

Ongoing advancements in materials and technology are leading to the development of more efficient and reliable current sensing resistors. Innovations in manufacturing processes and materials can enhance performance and reduce costs.

B. Integration with Smart Systems

As electronic devices become smarter, the integration of current sensing resistors with smart systems is expected to increase. This integration will enable more sophisticated monitoring and control capabilities.

C. Miniaturization and Enhanced Performance

The trend toward miniaturization in electronics is driving the development of smaller, more efficient current sensing resistors. These components will continue to evolve to meet the demands of compact and high-performance applications.

VIII. Conclusion

A. Recap of Key Features

Current sensing resistors play a vital role in modern electronics, providing accurate current measurement and enabling efficient operation. Key features such as resistance value, power rating, size, material composition, and noise characteristics are essential considerations for designers.

B. Importance of Choosing the Right Current Sensing Resistor

Selecting the appropriate current sensing resistor is crucial for ensuring accurate measurements and reliable performance in electronic circuits. Designers must carefully evaluate application requirements, environmental factors, and manufacturer specifications.

C. Final Thoughts on the Role of Current Sensing Resistors in Modern Electronics

As technology continues to advance, the importance of current sensing resistors will only grow. Their ability to provide real-time current monitoring and control is essential for optimizing performance and ensuring the safety of electronic devices.

IX. References

A. Academic Journals

- IEEE Transactions on Industrial Electronics

- Journal of Electronic Materials

B. Industry Reports

- Market Research Reports on Current Sensing Technologies

- Industry Analysis on Power Management Solutions

C. Manufacturer Datasheets

- Datasheets from leading manufacturers of current sensing resistors, such as Vishay, Bourns, and Ohmite.

This comprehensive overview of current sensing resistors highlights their significance in electronic design and the critical features that engineers must consider when selecting these components. By understanding the principles and applications of current sensing resistors, designers can enhance the performance and reliability of their electronic systems.