What is the Function of the Latest Resistors and What Are Their Manufacturing Processes?

I. Introduction

Resistors are fundamental components in electronic circuits, serving a critical role in controlling the flow of electric current. By providing resistance, they help manage voltage levels and protect sensitive components from damage. Over the years, the evolution of resistors has been marked by significant advancements in both their functionality and manufacturing processes. This blog post will explore the latest developments in resistor technology, their functions, and the processes involved in their production.

II. The Function of Resistors

A. Basic Principles of Resistance

At the heart of resistor functionality lies Ohm's Law, which states that the current (I) flowing through a conductor between two points is directly proportional to the voltage (V) across the two points and inversely proportional to the resistance (R). This relationship is expressed mathematically as V = I × R. Resistors play a vital role in controlling current and voltage in electronic circuits, ensuring that components operate within their specified limits.

B. Types of Resistors and Their Specific Functions

Resistors come in various types, each designed for specific applications:

1. **Fixed Resistors**: These resistors have a constant resistance value and are commonly used in circuits to limit current, divide voltages, and set bias points.

2. **Variable Resistors**: Also known as potentiometers and rheostats, these resistors allow for adjustable resistance. They are often used in applications such as volume controls in audio equipment.

3. **Specialty Resistors**: These include thermistors, which change resistance with temperature, and photoresistors, which vary resistance based on light exposure. Such resistors are crucial in temperature sensing and light detection applications.

C. Applications of Resistors in Modern Electronics

Resistors are integral to various applications in modern electronics:

1. **Signal Processing**: In audio and radio frequency circuits, resistors help shape and filter signals, ensuring clarity and fidelity.

2. **Power Management**: Resistors are used in power supply circuits to manage voltage levels and distribute power efficiently.

3. **Circuit Protection**: By limiting current flow, resistors protect sensitive components from damage due to overcurrent conditions.

III. Latest Developments in Resistor Technology

A. Advances in Materials Used for Resistors

Recent advancements in materials have significantly improved resistor performance:

1. **Carbon Film and Metal Film Resistors**: These resistors offer better stability and precision compared to traditional carbon composition resistors.

2. **Thin-Film and Thick-Film Technologies**: These methods allow for the production of resistors with precise resistance values and improved thermal stability.

3. **Emerging Materials**: Innovations in materials such as graphene and nanomaterials are paving the way for resistors with enhanced performance characteristics, including higher conductivity and lower noise levels.

B. Miniaturization and Integration in Modern Devices

The trend towards miniaturization has led to the development of surface-mount technology (SMT) resistors. These compact components are designed for automated assembly, making them ideal for modern electronic devices where space is at a premium. Chip resistors, which are small and lightweight, are widely used in smartphones, tablets, and other portable electronics.

C. Enhanced Performance Characteristics

The latest resistors exhibit improved performance characteristics:

1. **Precision Resistors**: These resistors offer tight tolerance levels, making them suitable for applications requiring high accuracy.

2. **High-Power and High-Frequency Resistors**: Designed to handle greater power loads and operate effectively at high frequencies, these resistors are essential in telecommunications and power electronics.

3. **Temperature Stability and Tolerance Improvements**: Advances in manufacturing processes have led to resistors that maintain their performance across a wider range of temperatures, enhancing reliability in various environments.

IV. Manufacturing Processes of Resistors

A. Overview of Resistor Manufacturing

The manufacturing of resistors begins with the selection of raw materials, which are critical to the performance and reliability of the final product. Design and engineering considerations also play a significant role in ensuring that resistors meet specific application requirements.

B. Traditional Manufacturing Methods

1. **Carbon Composition Resistors**: These resistors are made by mixing carbon particles with a binding material. While they are cost-effective, they have limitations in terms of precision and stability.

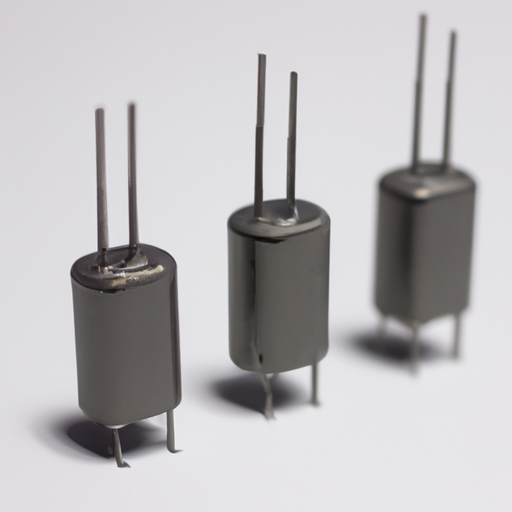

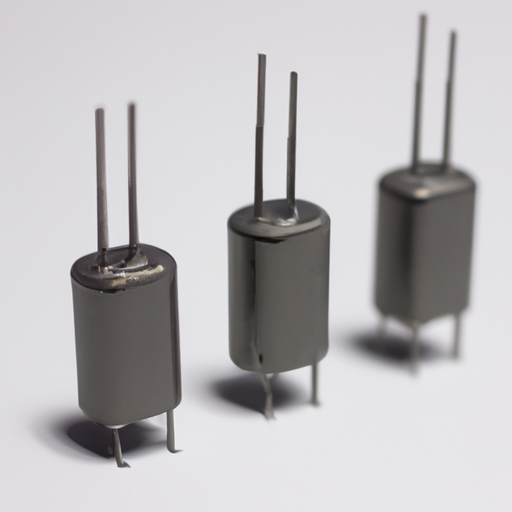

2. **Wire-Wound Resistors**: Constructed by winding a metal wire around a ceramic or plastic core, these resistors are known for their high power handling capabilities but can be bulkier than other types.

C. Modern Manufacturing Techniques

1. **Thin-Film and Thick-Film Deposition Processes**: These techniques involve depositing a thin or thick layer of resistive material onto a substrate, allowing for precise control over resistance values.

2. **Screen Printing and Laser Trimming**: Screen printing is used to apply resistive inks onto substrates, while laser trimming allows for fine-tuning of resistance values post-manufacturing.

3. **Automated Assembly and Quality Control**: Modern manufacturing facilities utilize automation to enhance production efficiency and ensure consistent quality through rigorous testing and quality control measures.

D. Environmental Considerations in Manufacturing

As the electronics industry becomes increasingly aware of its environmental impact, manufacturers are adopting sustainable practices. This includes using eco-friendly materials, minimizing waste, and implementing recycling programs for electronic components.

V. Challenges and Future Trends

A. Challenges in Resistor Technology

Despite advancements, the resistor industry faces several challenges:

1. **Demand for Higher Precision and Reliability**: As electronic devices become more complex, the need for resistors with tighter tolerances and greater reliability continues to grow.

2. **Cost Pressures and Competition**: Manufacturers must balance the cost of high-quality materials and advanced manufacturing processes with competitive pricing.

B. Future Trends in Resistor Design and Manufacturing

The future of resistor technology is promising, with several trends emerging:

1. **Smart Resistors and IoT Integration**: The integration of resistors into smart devices and the Internet of Things (IoT) is expected to drive innovation, leading to the development of resistors that can communicate and adapt to changing conditions.

2. **Innovations in Materials and Processes**: Ongoing research into new materials and manufacturing techniques will likely yield resistors with enhanced performance characteristics.

3. **The Role of AI and Automation in Manufacturing**: The adoption of artificial intelligence and automation in manufacturing processes will improve efficiency, reduce costs, and enhance quality control.

VI. Conclusion

Resistors are indispensable components in electronic circuits, playing a vital role in controlling current and voltage. The advancements in resistor technology and manufacturing processes have led to improved performance, miniaturization, and integration into modern devices. As the electronics landscape continues to evolve, the future of resistors looks bright, with innovations on the horizon that promise to enhance their functionality and reliability.

VII. References

1. Academic journals and articles on resistor technology.

2. Industry reports and white papers discussing advancements in electronics.

3. Books and online resources focused on electronics and resistor manufacturing processes.

In summary, resistors are not just passive components; they are essential players in the intricate world of electronics, continuously evolving to meet the demands of modern technology.

What is the Function of the Latest Resistors and What Are Their Manufacturing Processes?

I. Introduction

Resistors are fundamental components in electronic circuits, serving a critical role in controlling the flow of electric current. By providing resistance, they help manage voltage levels and protect sensitive components from damage. Over the years, the evolution of resistors has been marked by significant advancements in both their functionality and manufacturing processes. This blog post will explore the latest developments in resistor technology, their functions, and the processes involved in their production.

II. The Function of Resistors

A. Basic Principles of Resistance

At the heart of resistor functionality lies Ohm's Law, which states that the current (I) flowing through a conductor between two points is directly proportional to the voltage (V) across the two points and inversely proportional to the resistance (R). This relationship is expressed mathematically as V = I × R. Resistors play a vital role in controlling current and voltage in electronic circuits, ensuring that components operate within their specified limits.

B. Types of Resistors and Their Specific Functions

Resistors come in various types, each designed for specific applications:

1. **Fixed Resistors**: These resistors have a constant resistance value and are commonly used in circuits to limit current, divide voltages, and set bias points.

2. **Variable Resistors**: Also known as potentiometers and rheostats, these resistors allow for adjustable resistance. They are often used in applications such as volume controls in audio equipment.

3. **Specialty Resistors**: These include thermistors, which change resistance with temperature, and photoresistors, which vary resistance based on light exposure. Such resistors are crucial in temperature sensing and light detection applications.

C. Applications of Resistors in Modern Electronics

Resistors are integral to various applications in modern electronics:

1. **Signal Processing**: In audio and radio frequency circuits, resistors help shape and filter signals, ensuring clarity and fidelity.

2. **Power Management**: Resistors are used in power supply circuits to manage voltage levels and distribute power efficiently.

3. **Circuit Protection**: By limiting current flow, resistors protect sensitive components from damage due to overcurrent conditions.

III. Latest Developments in Resistor Technology

A. Advances in Materials Used for Resistors

Recent advancements in materials have significantly improved resistor performance:

1. **Carbon Film and Metal Film Resistors**: These resistors offer better stability and precision compared to traditional carbon composition resistors.

2. **Thin-Film and Thick-Film Technologies**: These methods allow for the production of resistors with precise resistance values and improved thermal stability.

3. **Emerging Materials**: Innovations in materials such as graphene and nanomaterials are paving the way for resistors with enhanced performance characteristics, including higher conductivity and lower noise levels.

B. Miniaturization and Integration in Modern Devices

The trend towards miniaturization has led to the development of surface-mount technology (SMT) resistors. These compact components are designed for automated assembly, making them ideal for modern electronic devices where space is at a premium. Chip resistors, which are small and lightweight, are widely used in smartphones, tablets, and other portable electronics.

C. Enhanced Performance Characteristics

The latest resistors exhibit improved performance characteristics:

1. **Precision Resistors**: These resistors offer tight tolerance levels, making them suitable for applications requiring high accuracy.

2. **High-Power and High-Frequency Resistors**: Designed to handle greater power loads and operate effectively at high frequencies, these resistors are essential in telecommunications and power electronics.

3. **Temperature Stability and Tolerance Improvements**: Advances in manufacturing processes have led to resistors that maintain their performance across a wider range of temperatures, enhancing reliability in various environments.

IV. Manufacturing Processes of Resistors

A. Overview of Resistor Manufacturing

The manufacturing of resistors begins with the selection of raw materials, which are critical to the performance and reliability of the final product. Design and engineering considerations also play a significant role in ensuring that resistors meet specific application requirements.

B. Traditional Manufacturing Methods

1. **Carbon Composition Resistors**: These resistors are made by mixing carbon particles with a binding material. While they are cost-effective, they have limitations in terms of precision and stability.

2. **Wire-Wound Resistors**: Constructed by winding a metal wire around a ceramic or plastic core, these resistors are known for their high power handling capabilities but can be bulkier than other types.

C. Modern Manufacturing Techniques

1. **Thin-Film and Thick-Film Deposition Processes**: These techniques involve depositing a thin or thick layer of resistive material onto a substrate, allowing for precise control over resistance values.

2. **Screen Printing and Laser Trimming**: Screen printing is used to apply resistive inks onto substrates, while laser trimming allows for fine-tuning of resistance values post-manufacturing.

3. **Automated Assembly and Quality Control**: Modern manufacturing facilities utilize automation to enhance production efficiency and ensure consistent quality through rigorous testing and quality control measures.

D. Environmental Considerations in Manufacturing

As the electronics industry becomes increasingly aware of its environmental impact, manufacturers are adopting sustainable practices. This includes using eco-friendly materials, minimizing waste, and implementing recycling programs for electronic components.

V. Challenges and Future Trends

A. Challenges in Resistor Technology

Despite advancements, the resistor industry faces several challenges:

1. **Demand for Higher Precision and Reliability**: As electronic devices become more complex, the need for resistors with tighter tolerances and greater reliability continues to grow.

2. **Cost Pressures and Competition**: Manufacturers must balance the cost of high-quality materials and advanced manufacturing processes with competitive pricing.

B. Future Trends in Resistor Design and Manufacturing

The future of resistor technology is promising, with several trends emerging:

1. **Smart Resistors and IoT Integration**: The integration of resistors into smart devices and the Internet of Things (IoT) is expected to drive innovation, leading to the development of resistors that can communicate and adapt to changing conditions.

2. **Innovations in Materials and Processes**: Ongoing research into new materials and manufacturing techniques will likely yield resistors with enhanced performance characteristics.

3. **The Role of AI and Automation in Manufacturing**: The adoption of artificial intelligence and automation in manufacturing processes will improve efficiency, reduce costs, and enhance quality control.

VI. Conclusion

Resistors are indispensable components in electronic circuits, playing a vital role in controlling current and voltage. The advancements in resistor technology and manufacturing processes have led to improved performance, miniaturization, and integration into modern devices. As the electronics landscape continues to evolve, the future of resistors looks bright, with innovations on the horizon that promise to enhance their functionality and reliability.

VII. References

1. Academic journals and articles on resistor technology.

2. Industry reports and white papers discussing advancements in electronics.

3. Books and online resources focused on electronics and resistor manufacturing processes.

In summary, resistors are not just passive components; they are essential players in the intricate world of electronics, continuously evolving to meet the demands of modern technology.