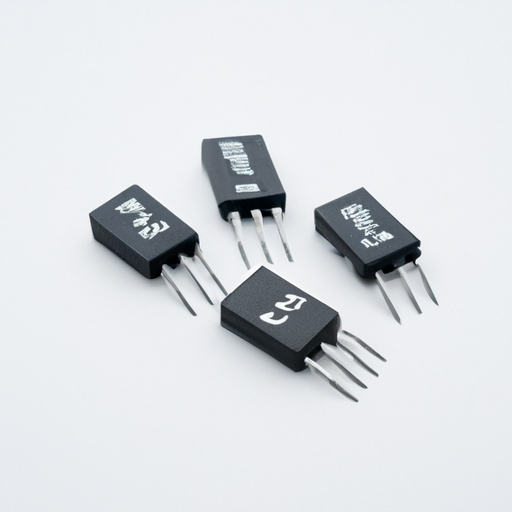

Overview of Varistors and MOVs

Varistors (Voltage-Dependent Resistors) and MOVs (Metal Oxide Varistors) are crucial components in electronic circuits, primarily utilized for voltage clamping and surge protection. They are engineered to shield sensitive electronic devices from voltage spikes, which can occur due to lightning strikes, power surges, or other transient events.

Core Functional Technology

1. Voltage Clamping: Varistors possess a nonlinear resistance characteristic, where their resistance drops significantly when the voltage surpasses a predetermined threshold (clamping voltage). This property enables them to divert excess voltage away from sensitive components, effectively protecting them from damage.

2. Energy Absorption: MOVs are capable of absorbing and dissipating substantial amounts of energy during transient events. This makes them particularly suitable for applications where high-energy surges are anticipated, such as in power distribution systems.

3. Fast Response Time: MOVs exhibit rapid response times, typically in the nanosecond range, which is essential for protecting electronic devices from fast transients. This quick action minimizes the risk of damage to sensitive components.

4. Temperature Stability: Modern MOVs are designed to function effectively across a broad temperature range, ensuring reliability in diverse environmental conditions. This stability is vital for applications in varying climates and operational settings.

5. Durability: Varistors are constructed to endure multiple surge events, although they may degrade over time. The design and material composition significantly influence their longevity and performance under repeated stress.

Application Development Cases

1. Consumer Electronics: Varistors are extensively used in power strips and surge protectors to safeguard devices such as televisions, computers, and home appliances from voltage spikes. For example, a power strip equipped with MOVs can effectively protect devices from surges caused by lightning or electrical faults.

2. Industrial Equipment: In industrial environments, MOVs are integrated into motor drives, control systems, and power supplies to shield against transients that may arise from switching operations or faults in the electrical grid. This protection is crucial for maintaining operational integrity and preventing equipment damage.

3. Telecommunications: MOVs are employed in telecom equipment to protect sensitive circuits from voltage surges caused by lightning strikes or disturbances in power lines. This ensures uninterrupted service and safeguards critical infrastructure.

4. Renewable Energy Systems: In solar inverters and wind turbines, MOVs are utilized to protect against voltage spikes that can occur during grid disturbances or lightning strikes. This protection is essential for ensuring the reliability and longevity of renewable energy systems, which are increasingly vital in modern energy solutions.

5. Automotive Applications: With the rise of electric vehicles (EVs), MOVs are increasingly used in battery management systems and charging stations to protect against voltage transients that can occur during charging cycles. This application is critical for enhancing the safety and reliability of EV technology.

Effective Design Considerations

1. Selection of Clamping Voltage: Choosing the appropriate clamping voltage is crucial. It should be low enough to protect the device but high enough to avoid nuisance tripping during normal operation. This balance is essential for effective surge protection.

2. Energy Rating: The energy rating of the MOV should align with the expected surge conditions. This involves assessing the maximum surge current and duration to ensure the MOV can handle the anticipated stress without failure.

3. Environmental Factors: Consideration of temperature, humidity, and potential exposure to contaminants is vital for ensuring the reliability of MOVs in specific applications. Proper environmental ratings can enhance the longevity and performance of these components.

4. Series and Parallel Configurations: Depending on the application requirements, MOVs can be connected in series or parallel to achieve desired voltage and current ratings. This flexibility allows for tailored solutions to meet specific protection needs.

5. Testing and Compliance: It is essential to ensure that the selected MOVs comply with relevant industry standards (e.g., UL, IEC) and undergo rigorous testing to validate their performance under expected conditions. Compliance with standards enhances trust in the reliability and safety of the components.

Conclusion

Varistors and MOVs are indispensable components in protecting electronic devices from voltage transients. Their ability to clamp voltage, absorb energy, and respond swiftly makes them essential in a wide range of applications, from consumer electronics to industrial systems. A thorough understanding of their core technologies and effective application development cases can lead to improved design choices and enhanced reliability in electronic systems, ultimately contributing to the longevity and safety of modern electronic devices.

Overview of Varistors and MOVs

Varistors (Voltage-Dependent Resistors) and MOVs (Metal Oxide Varistors) are crucial components in electronic circuits, primarily utilized for voltage clamping and surge protection. They are engineered to shield sensitive electronic devices from voltage spikes, which can occur due to lightning strikes, power surges, or other transient events.

Core Functional Technology

1. Voltage Clamping: Varistors possess a nonlinear resistance characteristic, where their resistance drops significantly when the voltage surpasses a predetermined threshold (clamping voltage). This property enables them to divert excess voltage away from sensitive components, effectively protecting them from damage.

2. Energy Absorption: MOVs are capable of absorbing and dissipating substantial amounts of energy during transient events. This makes them particularly suitable for applications where high-energy surges are anticipated, such as in power distribution systems.

3. Fast Response Time: MOVs exhibit rapid response times, typically in the nanosecond range, which is essential for protecting electronic devices from fast transients. This quick action minimizes the risk of damage to sensitive components.

4. Temperature Stability: Modern MOVs are designed to function effectively across a broad temperature range, ensuring reliability in diverse environmental conditions. This stability is vital for applications in varying climates and operational settings.

5. Durability: Varistors are constructed to endure multiple surge events, although they may degrade over time. The design and material composition significantly influence their longevity and performance under repeated stress.

Application Development Cases

1. Consumer Electronics: Varistors are extensively used in power strips and surge protectors to safeguard devices such as televisions, computers, and home appliances from voltage spikes. For example, a power strip equipped with MOVs can effectively protect devices from surges caused by lightning or electrical faults.

2. Industrial Equipment: In industrial environments, MOVs are integrated into motor drives, control systems, and power supplies to shield against transients that may arise from switching operations or faults in the electrical grid. This protection is crucial for maintaining operational integrity and preventing equipment damage.

3. Telecommunications: MOVs are employed in telecom equipment to protect sensitive circuits from voltage surges caused by lightning strikes or disturbances in power lines. This ensures uninterrupted service and safeguards critical infrastructure.

4. Renewable Energy Systems: In solar inverters and wind turbines, MOVs are utilized to protect against voltage spikes that can occur during grid disturbances or lightning strikes. This protection is essential for ensuring the reliability and longevity of renewable energy systems, which are increasingly vital in modern energy solutions.

5. Automotive Applications: With the rise of electric vehicles (EVs), MOVs are increasingly used in battery management systems and charging stations to protect against voltage transients that can occur during charging cycles. This application is critical for enhancing the safety and reliability of EV technology.

Effective Design Considerations

1. Selection of Clamping Voltage: Choosing the appropriate clamping voltage is crucial. It should be low enough to protect the device but high enough to avoid nuisance tripping during normal operation. This balance is essential for effective surge protection.

2. Energy Rating: The energy rating of the MOV should align with the expected surge conditions. This involves assessing the maximum surge current and duration to ensure the MOV can handle the anticipated stress without failure.

3. Environmental Factors: Consideration of temperature, humidity, and potential exposure to contaminants is vital for ensuring the reliability of MOVs in specific applications. Proper environmental ratings can enhance the longevity and performance of these components.

4. Series and Parallel Configurations: Depending on the application requirements, MOVs can be connected in series or parallel to achieve desired voltage and current ratings. This flexibility allows for tailored solutions to meet specific protection needs.

5. Testing and Compliance: It is essential to ensure that the selected MOVs comply with relevant industry standards (e.g., UL, IEC) and undergo rigorous testing to validate their performance under expected conditions. Compliance with standards enhances trust in the reliability and safety of the components.

Conclusion

Varistors and MOVs are indispensable components in protecting electronic devices from voltage transients. Their ability to clamp voltage, absorb energy, and respond swiftly makes them essential in a wide range of applications, from consumer electronics to industrial systems. A thorough understanding of their core technologies and effective application development cases can lead to improved design choices and enhanced reliability in electronic systems, ultimately contributing to the longevity and safety of modern electronic devices.